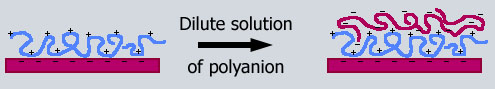

Polymers with charged groups (polyelectrolytes) allow one to build interesting multi-layer structures by the repeated and sequential dipping of charged substrates (such as treated glass, silicon, metals, or plastic) into a dilute solution of either positively or negatively charged polymer chains. Again, these functional groups need only be incorporated in modest fraction for this technique to be employed, allowing other specialty groups to be incorporated such as conductive, light-emitting, or bio-active groups. An advantage of this method of nano-device fabrication is that it is all aqueous, making it naturally compatible with many systems of biological interest, such as molecular recognition, sensing, or drug delivery.

This sequential dipping method has been demonstrated for hundreds of layers on a wide range of substrates (glass, Si, metals, etc.) and for practically any polymer which includes water-soluble ionic functionalities. This technique is also well-suited to forming small scale, 3-D films (in contrast to usual methods such as spin coating or vapour deposition which are limited to 2-D), and the coverage (lack of defects) is remarkably good. Despite much recent study however, many fundamental questions remain unanswered concerning the structure of the resulting layers. Information regarding the in situ conformation of the adsorbed layers is challenging to obtain, but is important to both the mechanistic study of the adsorption process, and for the insight that might be gained about more complex polyelectrolytes (such as proteins) adsorbed to surfaces.